Ballard unveils next generation zero-emission fuel cell stack for heavy duty motive market

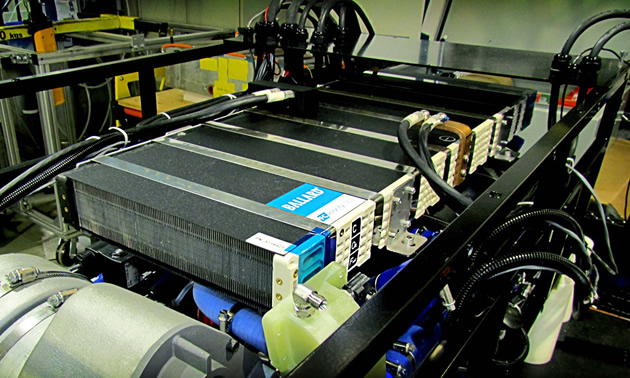

Ballard's new FCgen®-LCS high performance fuel cell stack will provide power for a range of Heavy Duty Motive applications, including buses, commercial trucks and trains. — Photo courtesy CNW Group/Ballard Power Systems Inc.

VANCOUVER and HANNOVER, Germany, Sept. 19, 2018 /CNW/ - Ballard Power Systems (NASDAQ: BLDP; TSX: BLDP) unveiled its next-generation high performance liquid-cooled fuel cell stack, the FCgen®-LCS, at the IAA Commercial Vehicles Trade Fair and Convention being held this week in Hannover, Germany.

The FCgen®-LCS features important design and performance enhancements, while also offering an impressive reduction in total-cost-of-ownership. This stack will be a core technology component of Ballard's 8th-generation power module portfolio for use in Heavy Duty Motive applications – including buses, commercial trucks and trains – planned for initial launch in 2019, and other applications such as forklifts.

Randy MacEwen, Ballard President and CEO said, "We are laser focused on strengthening the customer value proposition in Heavy Duty Motive. With the unveiling of the FCgen®-LCS, we are once again raising the bar in the industry. The FCgen®-LCS is expected to offer attractive customer value based on significantly reduced capital and operating costs, ultra-high durability, improved power density, impressive freeze start capability, enhanced efficiency, packaging flexibility, and high performance in a broad range of climatic conditions and duty cycles. With today's unveiling of the FCgen®-LCS stack and next year's planned launch of LCS-based power modules, Ballard will remain the market leader in zero-emission PEM fuel cell power solutions for the Heavy Duty Motive market."

Dr. Kevin Colbow, Ballard's Vice President – Technology and Product Development added, "The Ballard brand is synonymous with PEM fuel cell technology leadership. Our long-standing investment in PEM fuel cell research and product development, together with more than 8 million miles of on-road bus experience with customers across a variety of operating conditions, has resulted in this next generation, high performance PEM fuel cell stack."

Benefits of the FCgen®-LCS, compared to the current generation liquid-cooled fuel cell stack that it will replace, include:

- Lower Cost – Expected 40% reduction in total-cost-of-ownership, achieved through various design and processing improvements, including: improved durability; lower catalyst loading; increased power density; improved unit cell performance; greater efficiency; and optimized high-volume MEA manufacturing processes. (The total-cost-of-ownership comparison is based on life cycle cost of a 50-kilowatt fuel cell stack operating for 50,000 hours with a single refurbishment.)

- Ultra-Long Durability – Planned operating lifetime of more than 30,000 hours – which exceeds the useful lifetime of many vehicles – made possible through improved MEA design and processing, as well as the use of reusable carbon bi-polar plates and molded compression hardware.

- High Power Density – 33% increase in power density, reducing physical stack size for a given amount of power, and thereby enabling tighter packaging into limited available space.

- Freeze Start Capability – Able to start in cold temperatures from -25oC (-13oF).

- Higher Tolerance to Operating Conditions – Higher performance attributes of the stack enable tolerance to a wider range of operating conditions, including: cold weather conditions and freeze start capabilities; operation at temperatures of up to 85oC (185oF), thereby reducing cooling requirements; and compatibility with high- and low-pressure operating conditions.

- Simplified Systems Integration – Several important features simplify systems integration requirements, including: compact design; flexible packaging from 20-to-220 cells; ports located at both ends of the stack provide easier access for fluids as well as the ability to mount the stack in several different orientations; and expanded vehicle integration flexibility for both air and cooling systems, enabled by the stack's expanded range of operating pressure, humidity and temperature.

- Sustainability – FCgen®-LCS features key sustainability design characteristics, including: higher efficiency; the use of reusable low-cost carbon plates and compression hardware; and the ability to recover catalyst material from MEAs.

Ballard will be showcasing the FCgen®-LCS product in Hannover, Germany at the IAA Commercial Vehicles Trade Fair and Convention, September 19th-27th in Hall P11EG, booth 401-02. Further details, including contact information, can be found on the Company's website – www.ballard.com.

Ballard will continue to support the Company's existing customers where current generation FCvelocity®-9SSL fuel cell stack technology is used.

About Ballard Power Systems

Ballard Power Systems (NASDAQ: BLDP; TSX: BLDP) provides clean energy products that reduce customer costs and risks, and helps customers solve difficult technical and business challenges in their fuel cell programs. To learn more about Ballard, please visit www.ballard.com.