Fibre optics grows beyond telecom

Real-time sensing for wellbores, pipelines and tailings dams

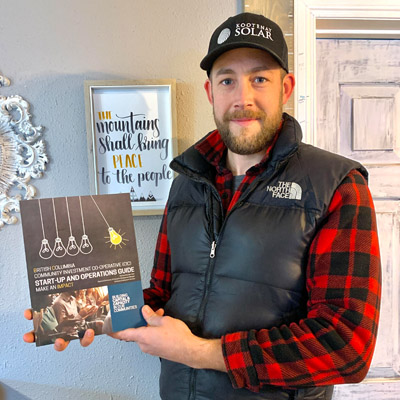

John Hull is founder and chief technology officer of Hifi Engineering Inc. — Photo courtesy Hifi Engineering

Pipelines.

Perhaps you’ve heard of them? Once a ubiquitous piece of infrastructure that barely registered in the Canadian consciousness beyond retirees looking for fixed income, pipelines have become mainstays of daily newscasts.

The pipeline debate is a complex one, but looking beyond the emotional and philosophical arguments that garner most of the attention, pipeline integrity and safety remain critical issues in the discussion. John Hull’s Calgary-based company, Hifi Engineering Inc., has developed a game-changing technology that addresses these concerns with previously unattainable precision.

The curiosity spark

Born in Calgary and raised in Red Deer, Hull, like most Albertans, was familiar with the oilpatch though not intimately involved in it. His entrepreneurial father found success in retail ventures.

Hull, chuckling, admitted, “I wasn’t exactly a scholar in high school.”

He did find electronics interesting, though. A two-year electronics engineering technology diploma at Southern Alberta Institute of Technology led to an additional two years at Lakehead University, where Hull received his bachelor of engineering (electrical). He spoke highly of Lakehead’s college transfer program designed specifically for engineering technologist graduates like himself.

Hull’s interest in sensor systems began while working at Schlumberger Limited, conducting open and cased hole logging for oil and gas projects in North America and the North Sea. What eventually became Hifi happened “accidentally.”

“I’d read about it somewhere … that others were using this fibre optic sensing,” said Hull.

The ability to use the fibre optic cable itself as a sensor opened intriguing new possibilities for full-length, real-time monitoring. Curious to explore this new technology, Hull saved some money and with a small investment from his father began testing “proof of concepts … on evenings and weekends.”

Those initial tests were successful but for the wrong reasons. Undaunted, Hull continued to refine his new hobby and eventually had a functional, albeit crude, prototype. It was enough to push forward to the next stage.

Hifi Engineering employee operating optical computing platform — Photo courtesy Hifi Engineering

A long-distance relationship

Initial development of Hull’s creation focused on down hole applications. Wellbore leak detection was a lucrative market and therefore a no-brainer for Hull with his background at Schlumberger. But Hull and his supporters were already looking towards a much bigger application for this technology.

“We knew that the real benefit of fibre was long distances,” said Hull. “The real power of fibre optics comes through when you have to do a hundred kilometres or a thousand kilometres.”

Conventional pipeline monitoring relies on two methods, each with inherent drawbacks. Mass balance, where monitors are placed every 50 kilometres and measure fluid-in versus fluid-out, has difficulty pinpointing the location of leaks between monitoring stations. One-time diagnostics, where people physically walk the line, relies on timing and luck; a leak could literally happen an hour after the inspector passes and not be found for days.

“They’re not monitoring every metre and they’re not monitoring 24/7,” said Hull.

This is where Hifi’s High-fidelity Dynamic Sensing (HDS) technology changes the game. By placing fibre optic cable in conduit near the pipeline, directly on the pipeline or within the pipeline itself, Hifi can continuously monitor acoustics, temperature and strain.

That steady, simultaneous stream of high-fidelity data is transmitted to a control room where sophisticated software distinguishes signal from noise and alerts operators of detected or potential leaks, thermal events, security intrusions and seismic impacts. More importantly, the system can pinpoint where these events occurred, enabling immediate and accurate response.

Staying grounded

As with the leap from down hole to pipelines, Hifi continues to find new markets for its product with the mining industry being the latest. Slurry pipelines are an obvious progression, but tailings dams offer a new and unique opportunity for Hull’s growing company.

“As they build these dams, we loop the fibre back and forth and then they put another layer [of earth] on, loop it back and forth … it takes years to do this,” said Hull. The result is “a three-dimensional strain indication” of the tailings dam, enabling the client to sense precursors to failure and seismic activity effects on the structure.

Past failures of tailings dams have had catastrophic impacts on surrounding environments and villages, with significant loss of life. Hull’s excitement to potentially eliminate such risks is obvious whenever he speaks of this latest venture for Hifi Engineering.

Eyes to the future

Looking forward, Hull sees tailings dams and pipelines as the primary source of growth for the company. Version two of Hifi’s patented HDS software is in the final stages of development, promising another step change in performance. Hull has assembled an exceptional management team, skilled technical staff and quality field crews to ensure his vision becomes reality.

“We’ve done most of the heavy lifting … in terms of [figuring] out how to get this stuff to work,” said Hull. “Most of the hiring we’re doing [now] is on the software side of it … artificial intelligence.”

That’s a familiar refrain these days as technology continues to transform industries. Hifi Engineering shows that this innovation can come from unlikely places—a high-tech success story in the heart of oil country.